Maintaining environmental compliance is essential throughout the industrial sectors – be it power plant, petrochemical, gas processing or oil & gas industry, or other process industries. Peace of mind for the operators or owners can be guaranteed only if operations are running smoothly, and avoiding penalties from regulators. AES can provide that peace of mind with our environmental products and services.

Boilers, generators, compressors, and process equipment like ovens, fryers, incinerators, and dryers are examples that contribute to greenhouse gas and other emissions.

Environmental emissions, such as air, waste, wastewater, storm water, etc. need to be regulated both locally and centrally (federally), and demand modern sophisticated products to comply with. Federal, State, and local regulations govern the amount and types of air emissions that can be released.

AES offers several products and services that help you complying with the norms at a competitive cost.

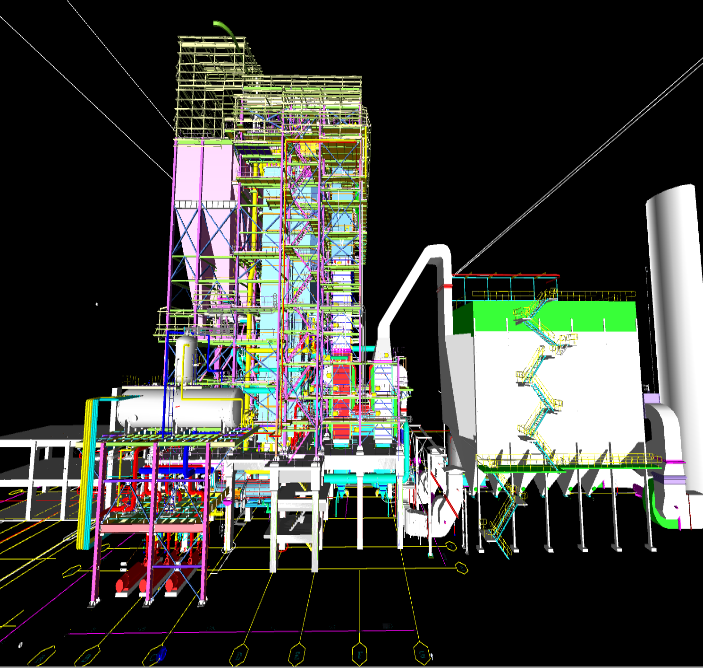

Total responsibility on Design, Engineering, Manufacture, Inspection, Testing, Erection & Commissioning of ESPs.

AES has associated with a company which has already supplied more than 50 nos. of ESPs for EPC & Stand-alone projects for all type of boiler applications with variety of fuels.

AES team has comprised of engineers with rich knowledge on Design, Engineering & Field services spanning over 32 years in various fields of Indian and International Power Plants, especially different types of ESPs.

AES also have a dedicated team of engineers at its engineering facilities at Tiruchirapalli.

Capability to select & engineer ESPs for very stringent particulate emission requirements of as low as 30 mg/Nm3.

Most of the ESPs engineered by AES team are for different types of boiler such as biomass traveling grate / reciprocating grate, fluidized bed boilers and pulverized coal fired boilers & Waste Heat Recovery Boilers – all meet the above guarantee.

AES has necessary expertise to carry out gas distribution tests at site.

The tests ensures compliance with the norms for uniform gas distribution & establishes correlation between results from CFD studies (if performed) and on-site measurements in full scale precipitator installation.

Full scale performance guarantee testing carried out in accordance with relevant national / international stanadards.

AES has mastered ESP technology as required to handle difficult - to - collect high resistive fly ashes with the engineering experience gathered with more than 50 ESPs.

AES has excellent knowlegde & expertise towards meeting stringent particulate emission norms at competitive terms.

Contact

Name: FRANKLIN KBR

Phone No: 97919 98876

Email: franklin.kbr@aes-group.in

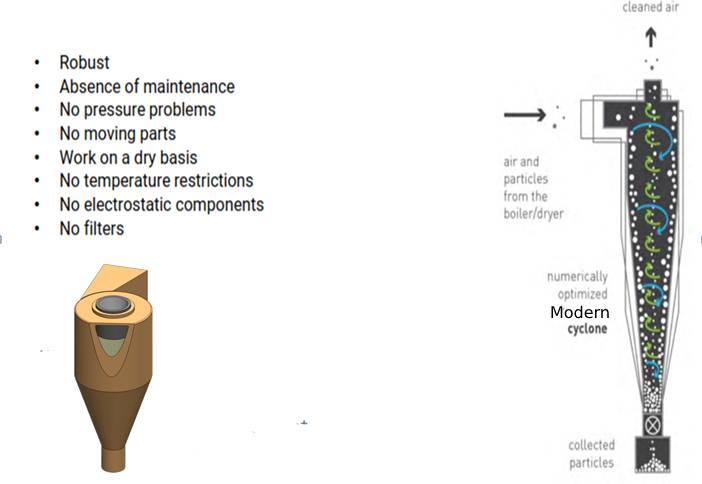

Due to their low efficiency, particularly for particles of size less than 10 µm, traditional cyclones and multi-cyclones cannot meet the present day demanding emission limits. They are not able to comply with the norms, for particulate matter (PM) emission control in high temperature exhaust streams from biomass or coal fired boilers and other heaters. Typically, the plants have to invest for a high efficiency expensive dedusting systems.

Bag filters (BF) are very efficient, but they can also be very high maintenance component requiring regular cleaning and new filter elements. Frequently released burning particles from Biomass and coal boilers damage filter elements and result in immediate increases in emissions. Solving this problem means spending money and production downtime.

Electrostatic Precipitators (ESPs) are very effective, but for a given range of dust resistivity. However, efficiency frequently drops outside this range as a consequence of temperature changes. The cost of retrofitting an ESP for process changes are out of reach for many companies.

Some plants intend to find Venturi Scrubbers as a good alternative for end stage dedusters. But, this is applicable only if the infrastructure to treat the liquid effluent is already in place. If not, the cost of secondary wet pollution restricts its usage.

Clients always need a dust collection system that is robust enough to operate for several years, with much lesser maintenance or operating costs, avoiding production downtime, that comes at a reasonable capital cost.

Modern cyclones have answer for these demands.

Traditionally cyclones have been designed and improved by empirical means. Companies use Computerized Flow Dynamics (CFD) for partial cyclone optimization but it is still incomplete for full cyclone optimization. This is because of the fact that the usual studies disregarded the particle agglomeration in the cyclone modelling.

Modern cyclones account for this and recent designs without any rotating parts in the high temperature zone results in higher particle collection efficiency and thus meeting even more stringent emission norms.

The same cyclone concepts help not only in emission control, but also in particle recovery in other process and pharma industries.

Efficient recovery of active pharmaceutical ingredients (APIs), chemical substances or food powders after drying applications such as spray and fluid bed drying is frequently a problem. The same problem occurs in many milling and micro ionization applications.

The preferred way to recover these sensitive and expensive products is with cyclone collectors due to their direct powder capture. Unlike bag filters or wet scrubbers, cyclones minimize filter or product contamination and product cross contamination and can easily handle a wide range of operating temperature, pressure and moisture conditions. Product losses due to cyclones low efficiency represents a high cost of lower yields.

Industrial customers need a cyclone system that dramatically increases powder yield, is easy and fast to clean and is efficient enough to comply with regulatory PM limits, thus avoiding the use of a bag filter.

AES can coordinate and arrange the supply these cyclones that are the products of an European OEM, that suit for both emission control and product recovery through their association with the OEM.

Contact

Name: VS Uppin

Phone No: 94206 97750

Email: uppin.vs@aes-group.in

FRESAFLO is a new, smart, wireless indoor air quality monitoring system, which can measure air temperature, humidity, pressure, particulates, CO2, and total volatile compounds (= TVOC), and send alarms to user for any activated measuring parameter. System enables also integrating new, external sensors according to customer’s preferences.

FRESAFLO system provides a continuous, local ad hoc storage for measured data, and transfers it also to cloud service for long term storage. Cloud service enables user to monitor real time data, receive reports, or review historical data for any measuring project, according to user’s authorization.

Due to efficient, wireless communication, it is easy to install sensor units and activate the system quickly. Without doubt, communication capacity is one of the key strengths of the system: sensor units, or nodes, create together a measuring network = mesh, which automatically creates and maintains data transfer connections, even if nodes were moved from a place to another. System can also be connected to a building automation system, if needed, and/or enhanced to a control system, e.g. for an air conditioning unit.

FRESAFLO is a perfect fit as the monitoring solution for smaller or larger premises, such as for an apartment/house, or an office, but for block of flats, commercial and industrial centers also.

FRESAFLO concept was developed in Finland and trademark is property of East-West Tech Solutions Oy.

AES is the exclusive representative of East West Tech Solutions Oy in India for the Sales and Service activities.

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in

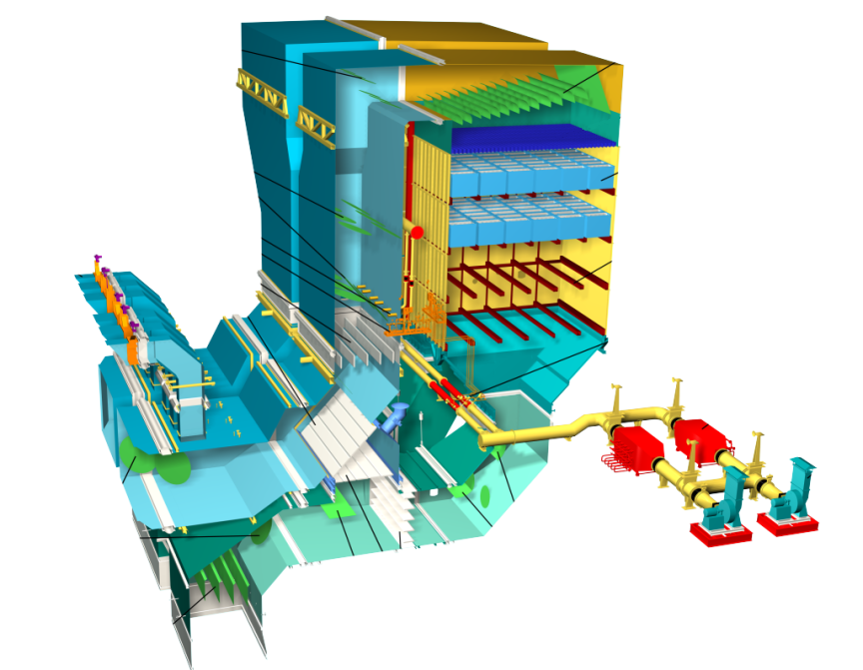

The market for Air Quality Control System (AQCS) systems in India has just exploded. The new emission norms announced by the Indian Ministry of Environment & Forests (MOE&F) in December 2015 are stringent by any yardstick and comparable with the standards in most Western countries.

For example: NOx emission targets will range from 600 mg/Nm3 to as low as 100 mg/Nm3 and SO2 targets range between 600 mg/Nm3 and 200 mg/Nm3 depending on their size and commissioning date.

The new regulations forced the Utilities and IPPs to cope up with challenging compliance schedules, high capital & operating costs, inadequate environmental cost recovery mechanisms, and technology challenges concerning high ash Indian coals. These uncertainties and pressures have created a highly cost-sensitive AQCS market and leading it to adopt a low cost approach to achieving compliance both in terms of capital cost and variable costs.

Most of the power producers have not had much experience in the selection, procurement, commissioning, operations, maintenance or commercial evaluation of AQCS systems. They were or still are in a learning mode as the industry grapples from lack of standardization in specifications.

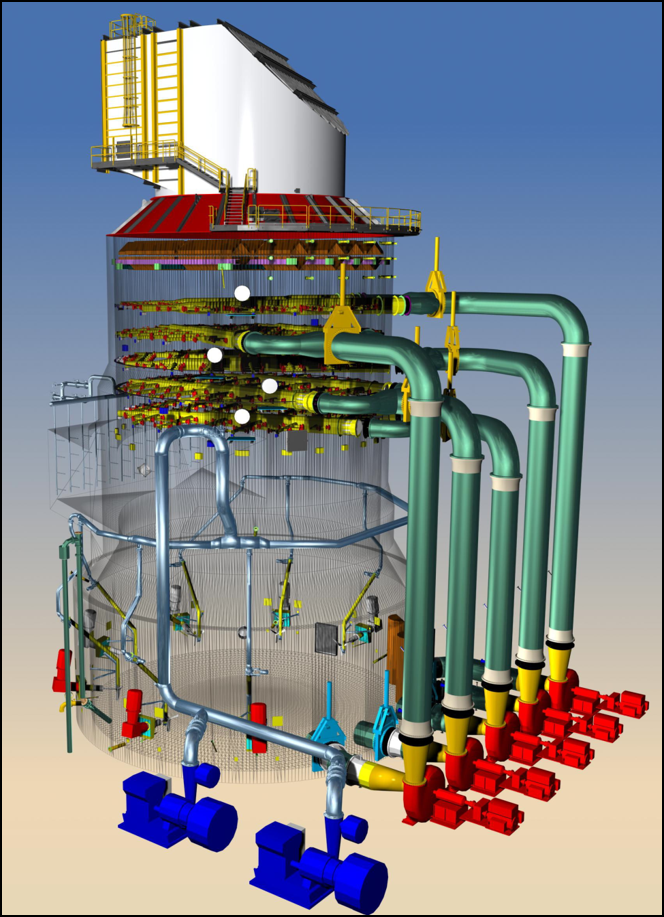

AES, can help OEMs or EPC contractors to meet this challenging market demands by offering a cost competitive engineering detailing services for both FGD and SCR systems. The AES team is highly experienced in detailing the sub-systems for the FGD and SCR plants from their association with the previous employers. Our engineers have worked on FGD contracts using both limestone slurry and sea-water systems of varying sizes between 250 MW and 800 MW.

AES can provide the following basic and detailed engineering services for FGD and SCR projects:

Contact

Name: Peter Lawrence

Phone No: 93604 02658

Email: lawrence.pa@aes-group.in

Sulphur oxides are the gaseous products of the oxidation of sulphur from the fuel burnt in the boilers by the oxygen in the combustion air. In FBC boilers, both BFB and CFB, the primary product of oxidation of the fuel sulphur is SO2, although a small amount of SO3 is also emitted.

The SO2 concentration resulting from the complete oxidation of the fuel sulphur without any reduction by any sorbent addition is called the uncontrolled SO2. Typical fuels result in complete combustion of their sulphur content, but in some cases a portion of the fuel sulphur will be bound in compounds preventing its oxidation.

Stringent emission norms demand the SO2 concentration in the flue gas that exit the boiler stack needs to be controlled to be within allowable limits. There can be some inherent sulphur capture by way of fuel ash constituents or otherwise it is typically required to add a sorbent (such as limestone or dolomite) to reduce the SO2 concentration in a FBC boiler.

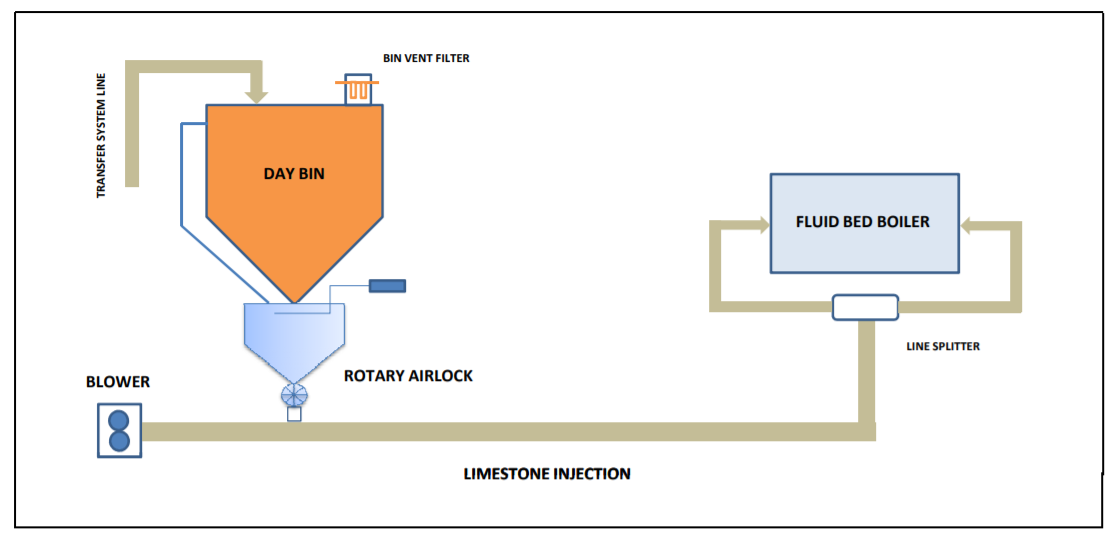

The amount of such sorbent needs to be estimated based on different operating conditions and the characteristics of the fuel and sorbent (like Ca/S ratio, extent of sulfation and calcination reactions, furnace temperature, sorbent reactivity, size distribution of sorbent, number of feed points, gas and sorbent residence time, extent of fly ash reinjection etc.,). A system is to be added or modified in the FBC boilers to feed the required sorbent into the boiler. AES can perform all these calculations and detailing of the sorbent feeding system for your BFB or CFB boilers and keep the SOx levels from your plant within the allowable limits.

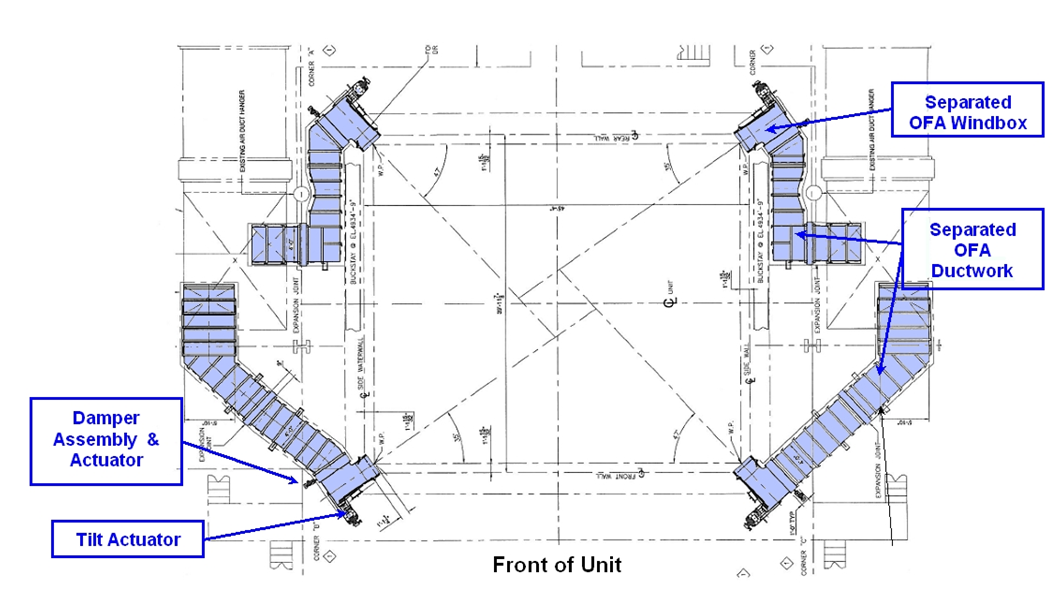

NOx emission in CFB boilers can be predicted by AES using a specially developed calculation model. NOx emissions can be a combination of NO, N2O and NO2 depending on the combustion of fuel nitrogen and thermally formed NOx because of high temperature combustion. NOx emissions must be reduced to be within allowable limits based on stringent emission norms and for this a Selective Non-Catalytic Reduction (SNCR) approach is carried out typically. SNCR is nothing but the injection of a NOx reducing agent. Typical such agents are ammonia, ammonium sulphate and urea. Our model predicts the extent of ammonia slip also.

The factors that impact the NOx reduction significantly in the SNCR approach are:

Our model takes into account several factors such as type of furnace, type of cyclone, geometry of the cyclone, furnace operating temperature, type of fuel, etc., to predict the amount of agent required.

AES would provide the system for your plant to meet the emission norms.

Contact

Name: Prakash

Phone No: 94893 31893

Email: engg4_prakash@aes-group.in