Today the prevailing challenges for plant operators are more restrictive emission norms, changes in fuel quality, fuel characteristics, ever increasing plant flexibility requirements, increased availability and efficient maintenance.

AES is capable of providing answers and solutions to these challenges based on a wide range of engineering expertise covering all types of boilers, combustion systems and pollution control equipment from chute to stack including all related auxiliary equipment.

AES is keen to support you and your maintenance activities to ensure the safe and economical operation of your plant. To achieve this we use in-house design and process tools combined with the comprehensive expertise of engineers derived from several decades of power plant design and operation.

For several reasons, many of the old boilers in process plants and in some areas the power plant itself are under long shut downs. Non-viability of operation from the fuel source point of view, operational costs, and so many other factors could have resulted in this dead-lock. However, the good news is that in the recent years the nearby industries look for either steam or power from these plants and new owners are approaching to take over the existing power plants and operate with different modus operandi.

The condition of these plants are to be studied, their residual life needs to be assessed and a judicial decision needs to be taken on how the plant can be effectively reused. In many cases, fuels are continuously changing, emission norms are getting more and more stringent, and customers’ demands for high Availability, Reliability and Efficiency are on the rise and these make the plants operation more challenging. These challenges demand the boiler or power plant equipment to be upgraded and modernized to counter the fuel issues, erosion and corrosion issues, efficiency of the plant, new fuel and ash handling challenges and availability etc.,

AES have in-house expertise to upgrade and improve the boiler performance to meet these challenging demands. AES engineers can survey and carry out an in-depth study to comprehend the current issues with the boiler, the reasons for those issues, the future demands and can come out with the several options and ways to meet those demands. What is required could be minor adjustments, or fine tuning, or upgrade or optimization or a major modification. All these can be met with the years and years of experience AES engineers have on this field.

AES can retain or increase the capacity of the steam generator or the power plant in such cases without diverging from the existing footprint based on a neutral analysis of the status quo and expert customer-specific product design.

AES can provide the customers with just the right solution for such cases, using our in-house calculation tools and our means of evaluation. A range of further engineering services will also help the customers optimize their subsequent processes.

AES long-term experience can be relied on, and AES know-how and background knowledge for the application of capacity upgrades and one-to one replacements for different design types can be trusted. AES are your ideal partner for design, manufacturing and supply, strongly respecting the economic aspects of your investment. AES job is to develop solutions for our customers’ tasks and make the plant ready to operate.

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in

Troubleshooting is the art of problem solving. It requires a system of thoughts and actions to overcome the challenges that your plant faces.

AES’ troubleshooting service includes the following aspects:

AES engineers are part of the troubleshooting team that resolved many boiler issues in the last thirty years in several plants with different types of boilers. AES, with such vast experience can be your trusted partner for any boiler issues that still lingers and impacts your plant.

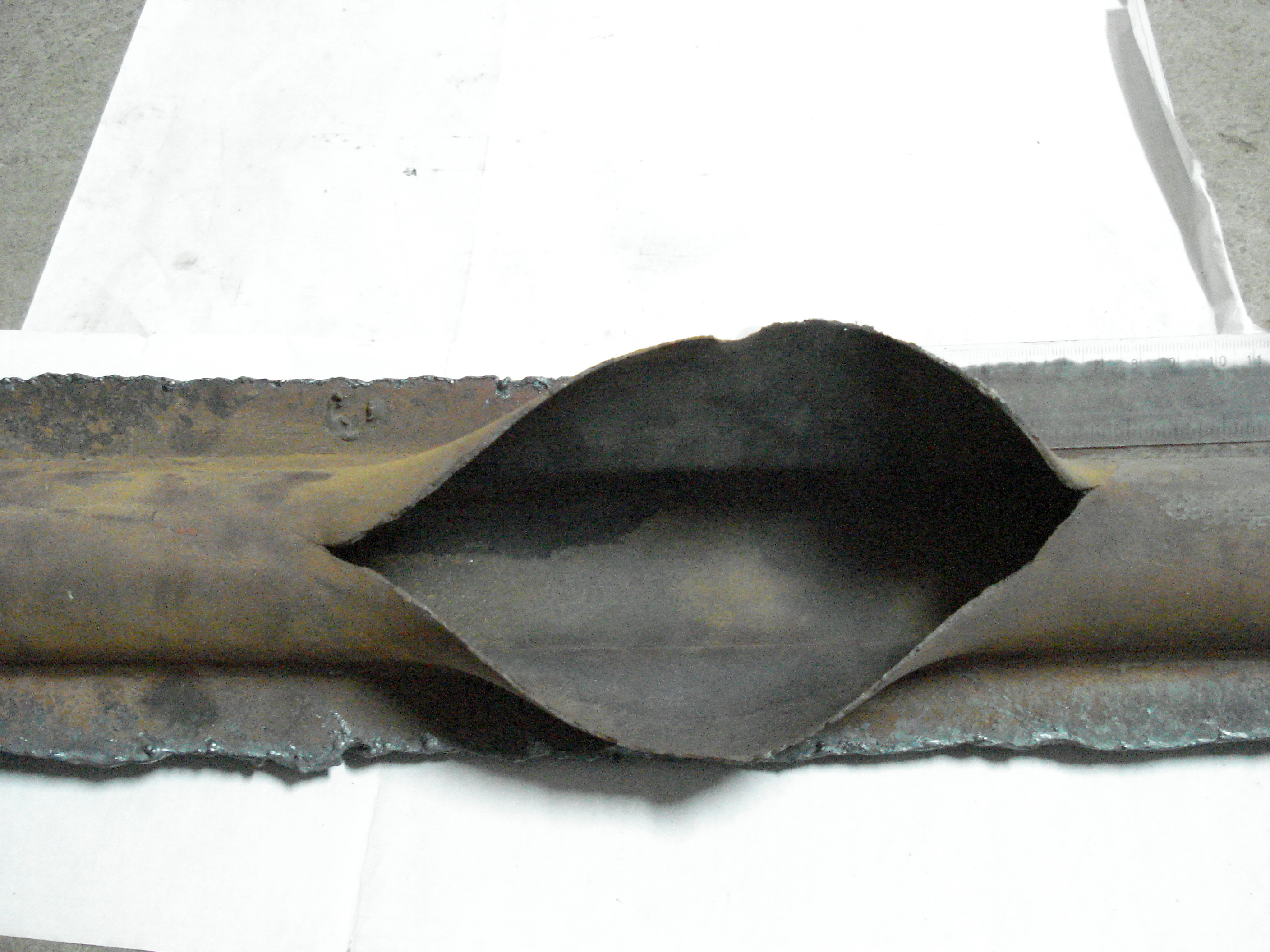

A Root Cause Analysis (RCA) can be conducted when a more formal approach is needed for failure assessment, where the goal is to prevent recurrence by addressing the root cause of a problem. RCA is typically a reactive method of identifying event(s) causes and problems, and then resolving them. Analysis is done after an event has occurred.

AES’ RCA service includes the following principles:

AES has carried out several RCA in the previous years in various boiler plants ranging from Captive to Cogen to Utility plants. AES will be a trusted team for resolving your plant’s issues that bother you for a long time.

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in

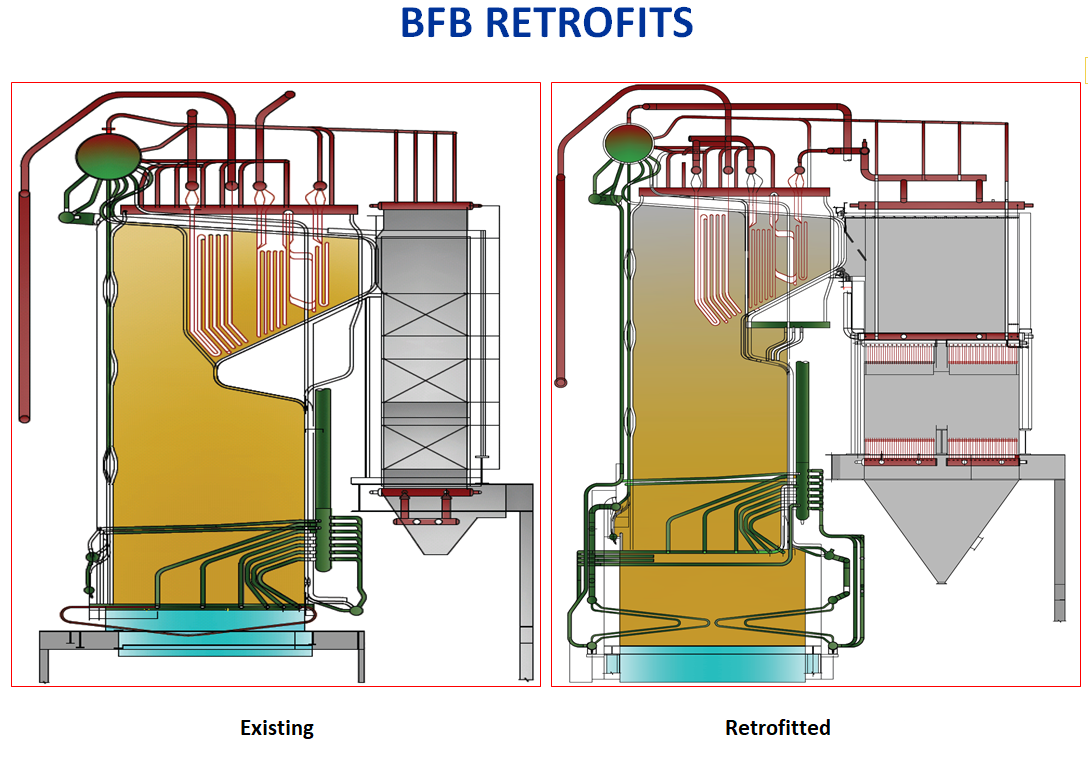

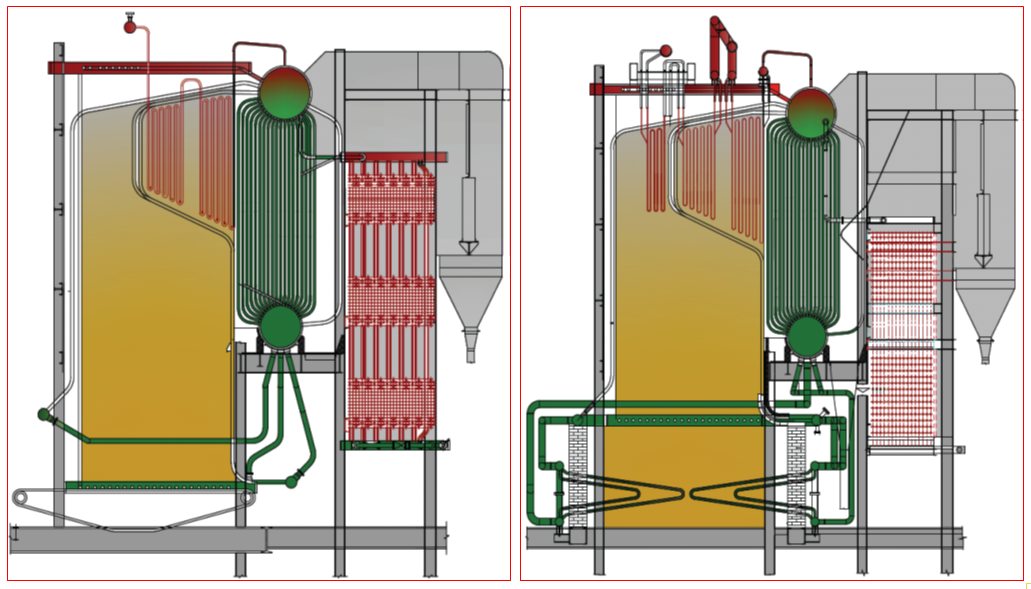

Almost all industrial units have old stoker fired boilers or old oil and gas fired boilers installed several years ago which are now inefficient either with the low grade fuels available or non-viable because of the high oil and gas prices. These old boilers can be retrofitted with BFB combustors with minimal modifications in the existing boiler’s pressure parts. By this retrofitting, not only the existing system is upgraded efficiently, but a capacity enhancement can also be achieved. AES can design and supply such BFB retrofits for any boilers without having limitations on the capacity or fuel type used.

AES have experience of working with several different boiler makers and their technologies and are highly knowledgeable of their features and potential issues. Therefore, AES have learned to select the most appropriate and practical solutions without getting tied to any technology providers or their standard solutions, and all the times approach the issues from the first principles. Hence, AES can recommend the most effective solution.

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in

As power plants age and face challenges such as poor quality during construction, maintenance budget cuts, shortage of on-site experts and increased load cycles to meet market demand, their lifetime performance is adversely affected. Owners and operators see it pertinent to assess and optimize the lifetime performance of their power plants, as unscheduled plant downtime and other unexpected costs impact their revenue.

As power plants age and face challenges such as poor quality during construction, maintenance budget cuts, shortage of on-site experts and increased load cycles to meet market demand, their lifetime performance is adversely affected. Owners and operators see it pertinent to assess and optimize the lifetime performance of their power plants, as unscheduled plant downtime and other unexpected costs impact their revenue.

AES approach:

During plant operation, power plant components may suffer decreased strength and reliability due to continuous exposure to high temperature, pressure, torsion, centrifugal loads and the cooling medium. The remaining lifetime of power plant components is determined by damage mechanisms such as creep damage, fatigue damage, crack propagation, and corrosion propagation. AES uses a combination of methods such as Non-Destructive Testing (NDT) and Finite Element Method (FEM) calculation for assessing the condition of the power plant components and the suitability of the power plant to further operate.

Beyond detecting flaws and cracks, AES evaluate the damage mechanisms with conventional NDT methods in order to obtain a comprehensive analysis of the power plant equipment condition. The NDT methods include:

NDT also helps to assess the extent of degradation of power plant components due to damage mechanisms by evaluating the hardness, embrittlement, microstructure and corrosion mechanism of the samples’ material properties. AES evaluate the plant’s operational history and perform an analysis of material properties to determine the remaining lifetime and future operation of the power plant.

Some failure mechanism cannot be detected by NDT methods. In such cases, computational methods such as Finite Element Analysis can be used to assess the condition of the power plant component. Through the use of FEM modelling, stress and fatigue calculations, fracture mechanisms, creep analysis and fluid dynamics, AES can develop a holistic view of the components and a reliable extrapolation of future material degradation.

AES can support you to make informed decisions regarding the safety of a power plant’s continued operation as well as its potential for future operation. Our understanding of how power plant components degrade with different factors enables us to assess the remaining lifetime of power plant components and determine the appropriate strategies such as additional monitoring, design modifications, exchange of components, inspection & maintenance, optimization of operation etc., that are required for lifetime extension.

Contact

Name: FRANKLIN KBR

Phone No: 97919 98876

Email: franklin.kbr@aes-group.in

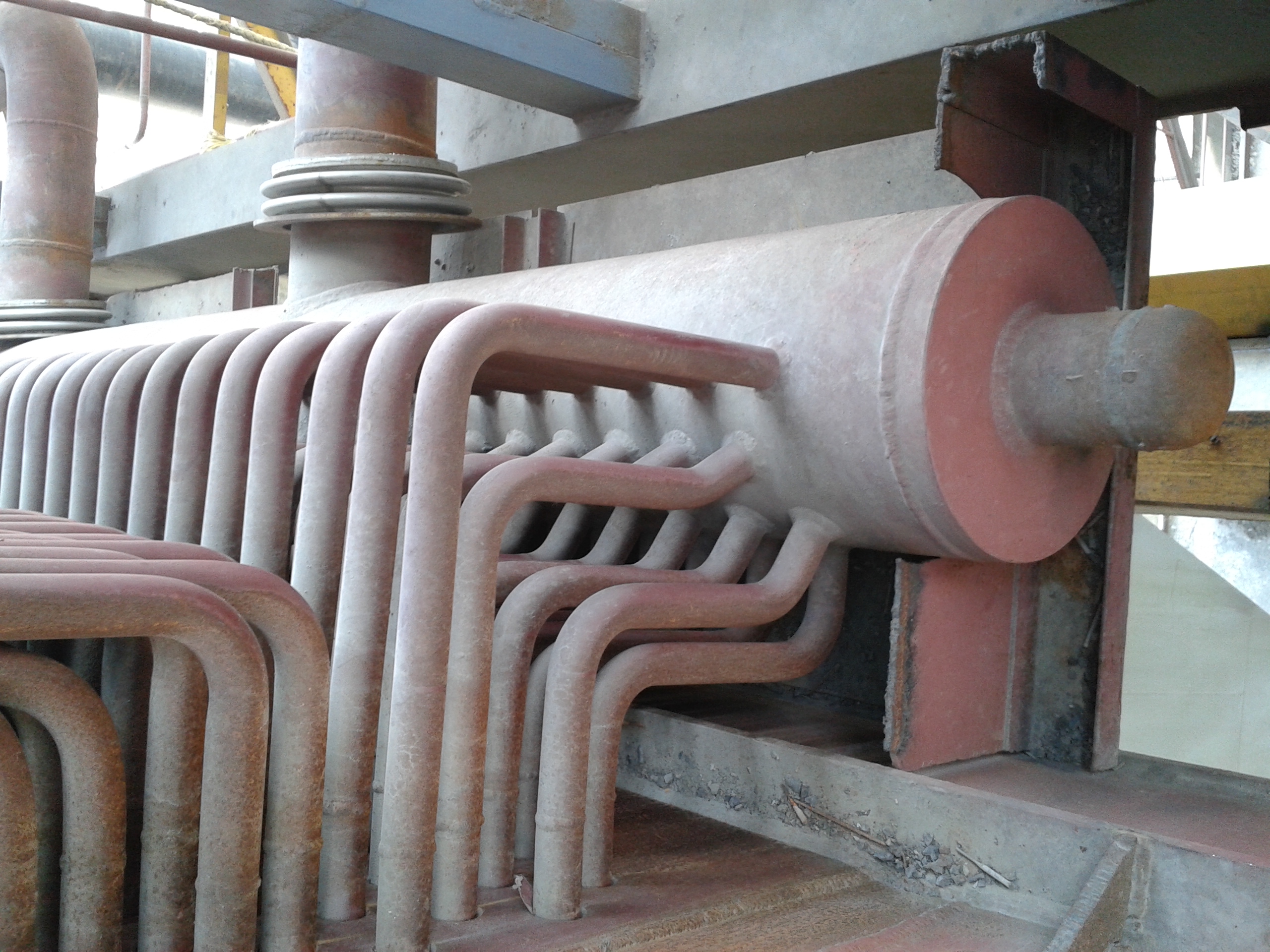

AES can undertake either in-kind replacement or newly designed replacement of pressure parts of the existing boilers. AES specializes in the design and our manufacturing partner specializes in the boiler pressure parts such as furnace wall panels, superheaters, economizers and cyclone panels from the manufacturing facility in Pune, India. AES can deliver ex-works or to a nearest port to the customer’s plant or to the customer’s site itself.

Our manufacturing partner’s fabrication facilities are IBR certified and also ASME certified with the S, U, PP and National Board R stamps. State of the art equipment for pressure part fabrication such as plate, tube and panel bending equipment, automatic, semi-automatic and manual welding equipment, fin welding machines, swaging facility, heat treatment furnaces etc.,

Contact

Name: Peter Lawrence

Phone No: 93604 02658

Email: lawrence.pa@aes-group.in

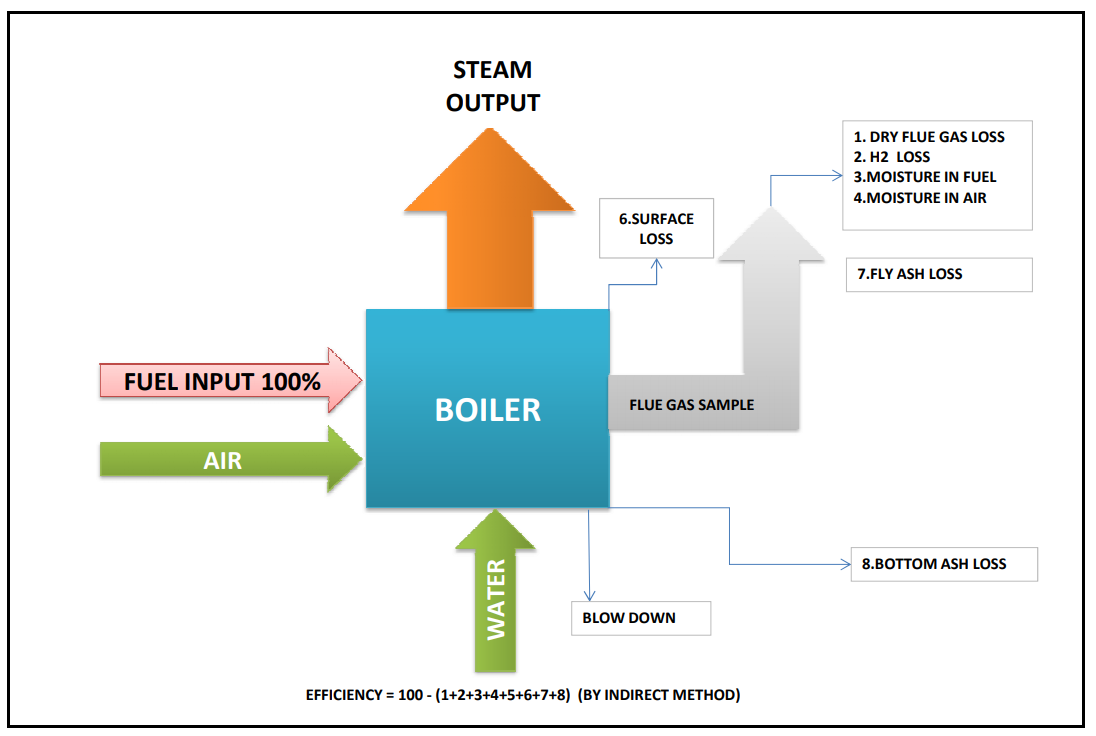

Boiler performance test programs have been conducted with various objectives including baseline performance characterization, new and retrofit equipment acceptance testing, and combustion and pollution system tuning and optimization. AES personnel are highly familiar with ASME test procedures. Some examples of test projects AES can take up are:

Contact

Name: Peter Lawrence

Phone No: 93604 02658

Email: lawrence.pa@aes-group.in