AES Engineering Consultancy wing is at your service to resolve the technical and commercial issues that may arise in any of the energy facilities, power plants and industrial applications that you operate.

We rely on the vast technical know-how of our team to go beyond the conventional consulting services so that you get real expertise.

AES offers a wide array of services such as:

Contact

Name: VS Uppin

Phone No: 94206 97750

Email: uppin.vs@aes-group.in

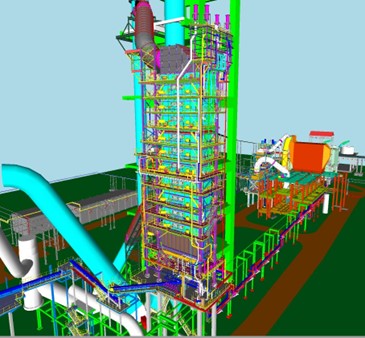

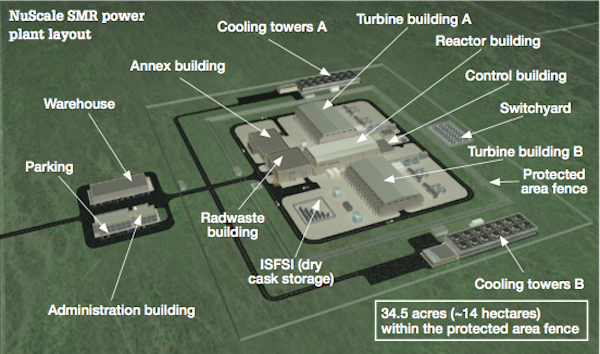

For nearly all kinds of power plant projects such as cogeneration, captive or utility plants in the field of conventional steam generator technology, AES have proven our performance, beginning with preparation of feasibility studies up to detailed design engineering.

The modern day power plants with sophisticated and ultra-modern boiler designs require a broad and deep expertise with decades of experience. All these features are covered by our engineers and technicians due to their academic education and employment history. Regardless of the type of boiler or fuel used, we at AES are able to solve complex requirements and tasks and offer customer-oriented and market-driven solutions.

Our approach from the fundamentals, upon clearly understanding the customers’ requirements would enable the right choice of power plant with the right boiler technology so that customers will not lose out on the Availability, Reliability and Efficiency.

Our networking strength and close business relationships with the manufacturers of other major power plant equipment like steam turbines, fuel and ash handling systems, pollution control equipment, and water treatment plant etc., help us arrive at the cost effective solutions on behalf of the customers.

Our feasibility study generally covers:

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in

AES team has involved in several Technical Due Diligence (TDD) exercises, analyzing and evaluating every technical aspect of a technology, product, service, people, infrastructure, processes and workflow, adherence to regulatory requirements and intellectual property holding etc., on behalf of an organization prior to furthering an investment by the organization. The TDD also includes the evaluation of the data security, disaster management plans in place. Thus, revealing the technical risks the organization may have before they fund on any particular technology or product.

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in

AES can act as Customer Consultants, Advisors and Owner’s Engineers. Owner’s engineer service can be provided from the early bidding stage till the take-over of the plant. AES can proactively support the Owner when involved from the bidding phase itself, to eliminate in advance the troubles that might arise later which would limit the operation of the plant. The involvement for the whole time of the project would help support the Owners with the valuable AES asset in the take-over and guarantee negotiations with plant equipment suppliers.

Our scope at a minimum cover:

Contact

Name: Peter Lawrence

Phone No: 93604 02658

Email: lawrence.pa@aes-group.in

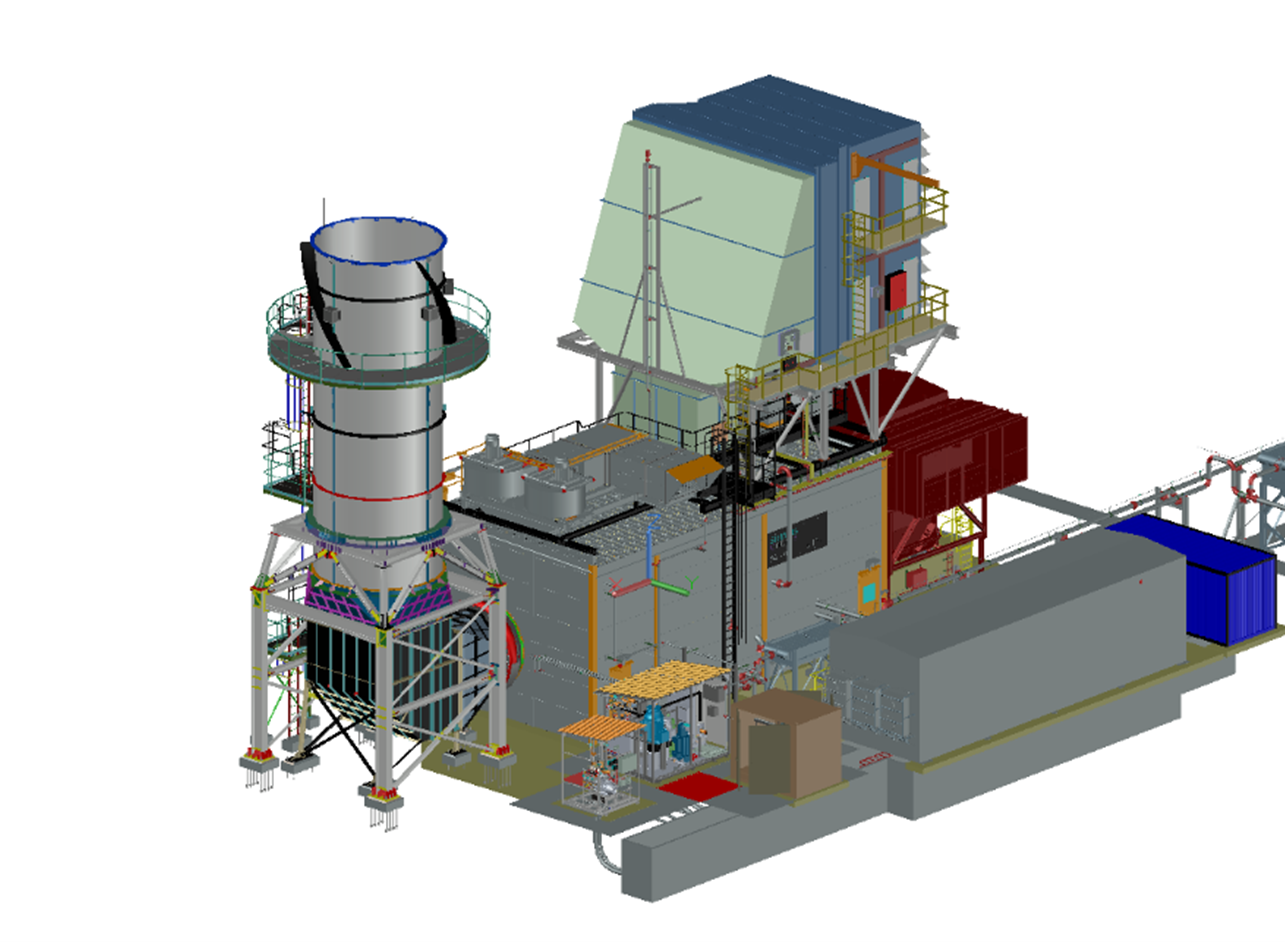

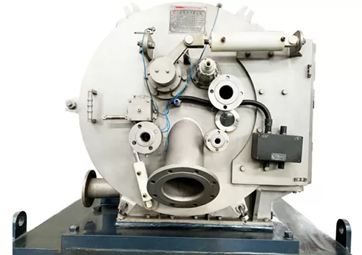

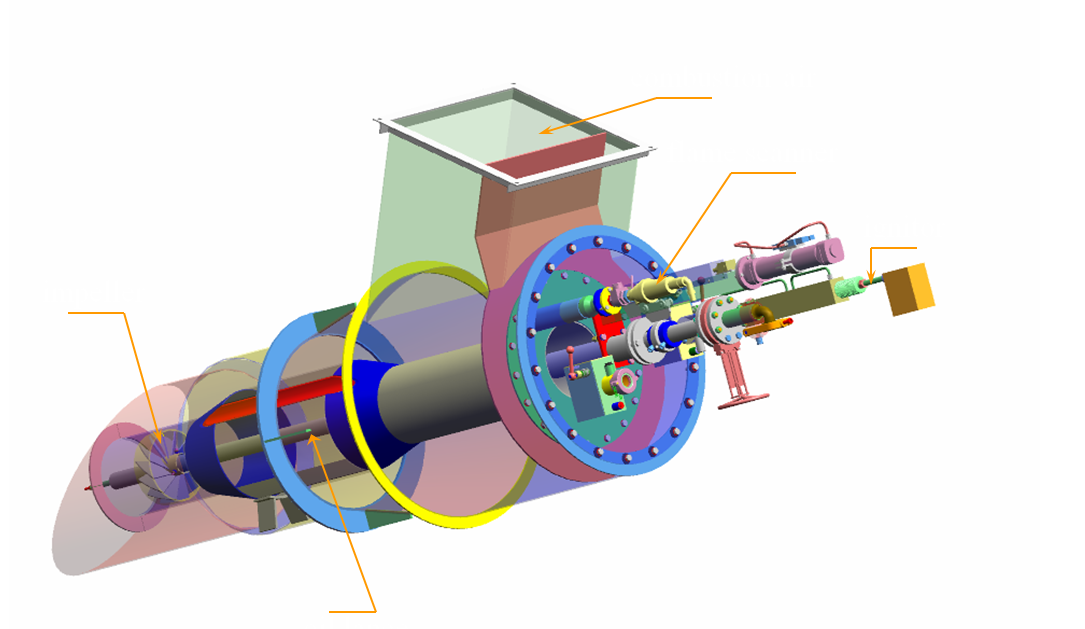

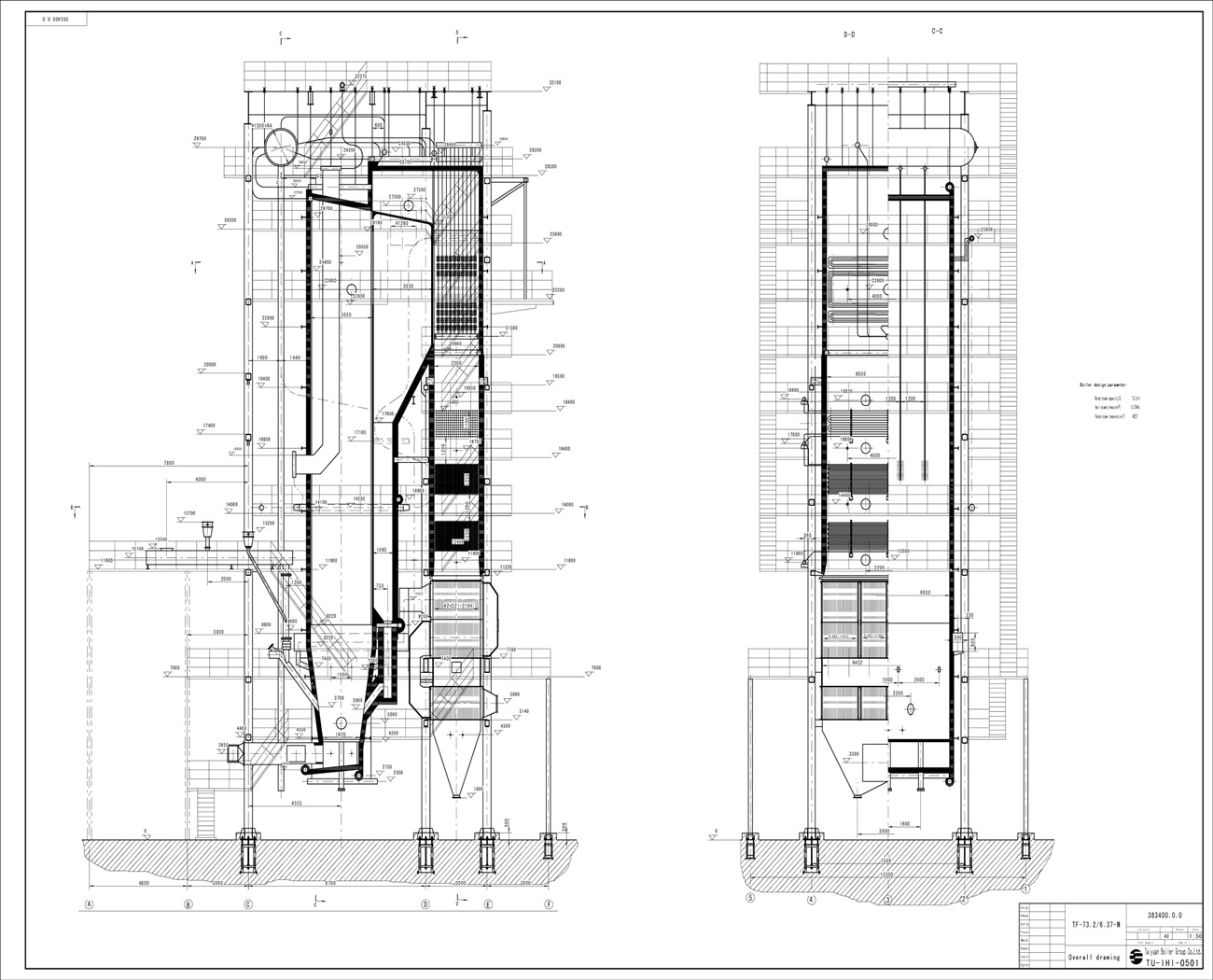

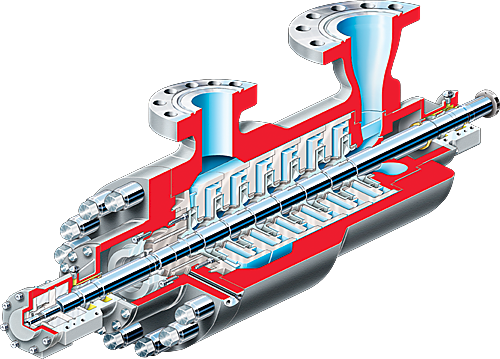

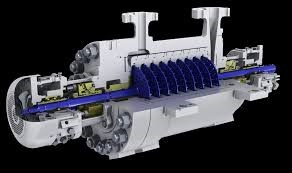

AES offers engineering support for several types of boilers for your thermal power plants, waste or sewage sludge incineration plants, refineries, petrochemical industries and process plants. AES advise on the appropriate technology and support you in the conceptual phase as well as during execution stage.

In close cooperation with customers, we can work on projects considering various standards such as IBR, ASME, EN and others.

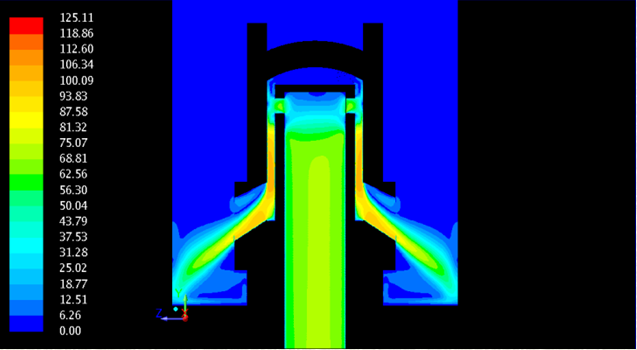

Basic and Performance Engineering is a core area with a lot of significance that decides the initial steps of the entire power plant design. It involves the complete sizing of the power plant equipment, ensures adequacy of the system considering several variables, and maximizes the reliability of the unit under steady state and transient conditions, checks safety of the plant, confirms easy operation of the plant with reduced maintenance and provides the necessary design redundancy to achieve the maximum plant availability.

Basic engineering covers:

AES engineers have an impeccable record in delivering these services by taking care of the following critical disciplines:

Detailed Engineering is an essential service in AES that ensures the proper conversion of the ideas generated in the Basic and Performance Engineering stage into an Executable version strictly within the norms and standards stipulated by the respective regulations that are in vogue in the countries where the products get manufactured and installed.

Development of detail design covers:

AES carries out the following detail engineering activities independently for specific projects as well as for the total power plant:

Contact

Name: Prakash

Phone No: 86752 85582

Email: prakash.a@aes-group.in

It is usual that the boiler Original Equipment Manufacturer (OEM) does not necessarily carry out all activities from construction to commission the unit and limits his service only to the scope of design and supply when the boiler is supplied. Perhaps, different agencies are involved for mechanical erection, commissioning and testing of equipment. In such cases, each agency does not take the responsibility for the other activity, neither schedule directly or indirectly. For example, the agency that is responsible for mechanical construction would not bother about the commissioning of the mechanical equipment that is being installed and so. In those cases, the Owner or the EPC contractor would necessarily need someone to play an advisory role and ensure still the recommended procedures are followed in such a way that overall project schedule is not affected.

AES can effectively play that role by providing the required advisory services and can be a bridge between the Owner and OEM/EPC contractor ensuring the unit is thoroughly tested, documented and optimized and can provide its best performance safely and with high reliability with normal operating efforts, when it is turned over to the end user.

Commissioning and boiler operation is the last phase of the project starting with Pre-Commissioning, continuing through Cold and Hot Commissioning and ending to Performance Guarantee test and Acceptance of the unit.

Pre-Commissioning is considered as final phase of erection and installation although the input and participation by commissioning personnel is necessary when the systems and equipment are turned over to commissioning and operation. In pre-commissioning, the equipment and systems are finalized and proven to be fit and ready for commissioning.

Cold commissioning is considered as the period from energizing the equipment to first fire of the boiler. During cold commissioning all auxiliary machinery and auxiliary systems shall be rotated and move tested without and with process fluids in the respective system.

Hot commissioning is defined as the period from the first fire of the boiler until the date of Unit Acceptance.

Contact

Name: Peter Lawrence

Phone No: 93604 02658

Email: lawrence.pa@aes-group.in

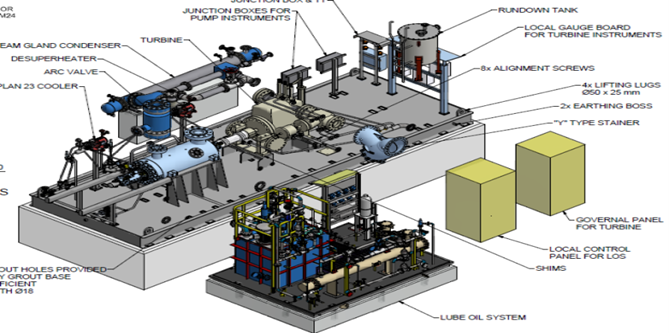

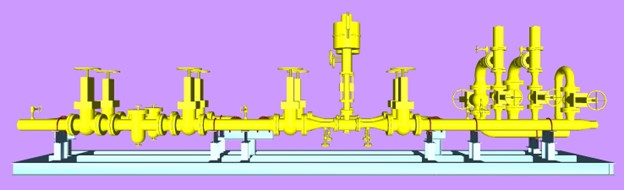

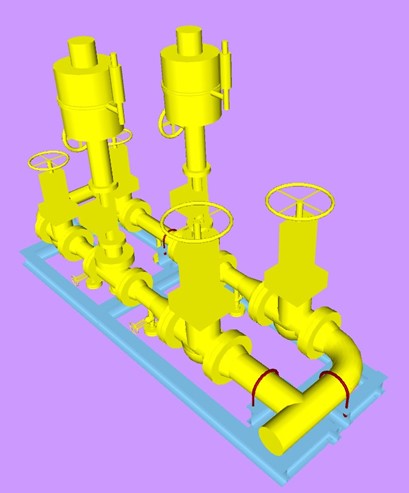

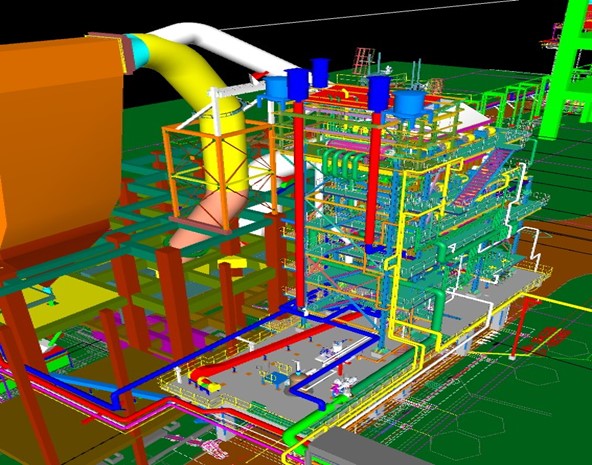

AES provide detail engineering services across all disciplines in the Petrochemical, Oil & Gas Processing sectors and Refineries. When the basic engineering is done either by FEED engineer or EPCM, we put the plans into practice by specifying all the equipment and structures in detail in order to install, construct and operate the plant. AES can also support in the Process Engineering design, if required.

Our process engineers can participate in the conceptual, basic and detailed engineering phases. Our team of engineers has a cumulative experience of 120 years in process engineering and have solid competence in multi-disciplinary plant engineering. They can perform for you:

Contact

Name: Prakash

Phone No: 86752 85582

Email: prakash.a@aes-group.in

Contact

Name: Peter Lawrence

Phone No: 93604 02658

Email: lawrence.pa@aes-group.in

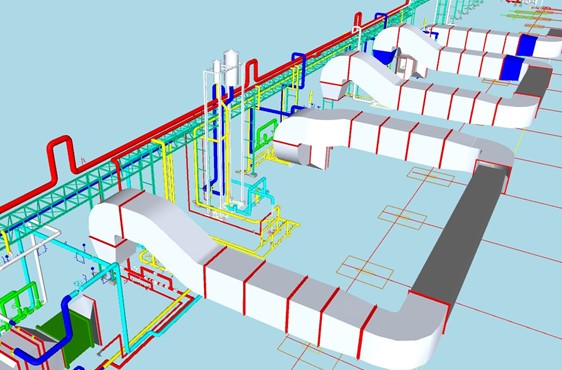

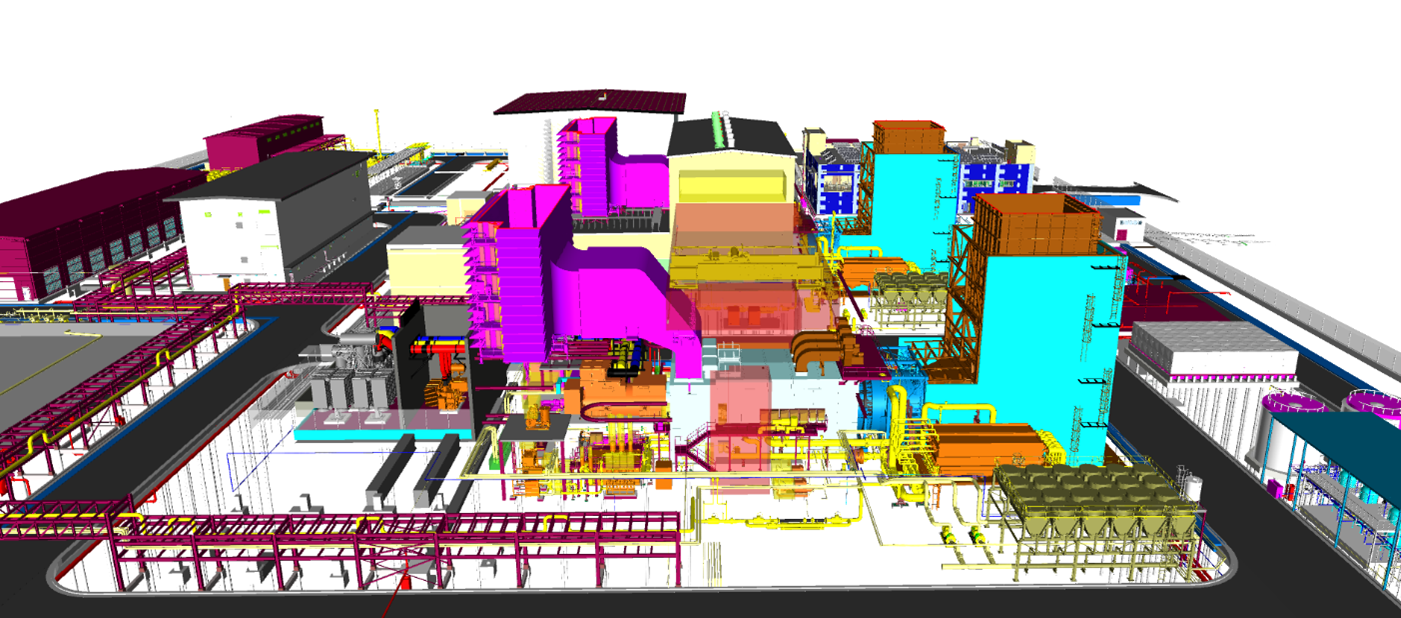

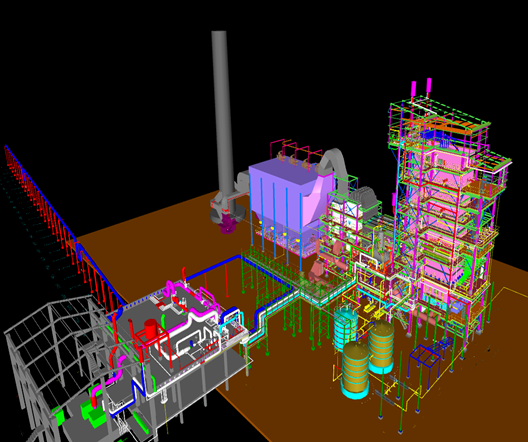

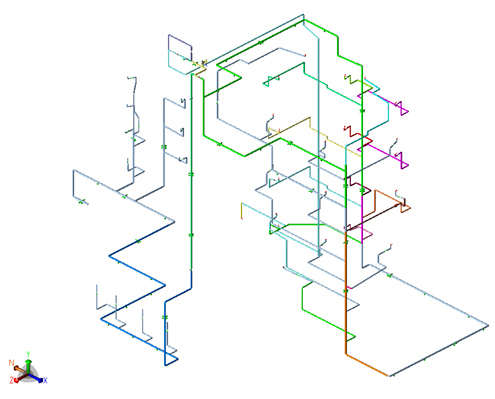

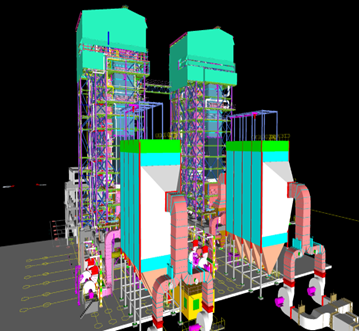

Our layout and piping engineers from AES are responsible for the plot plan preparation and piping design as well as the overall coordination of the plant 3D model including systematic reviews with all the disciplines resulting in a clash-free model.

Our core competencies in layout & piping design can be used as a consulting expert services or as a part in multi-discipline turnkey plant projects, whichever is your need.

Contact

Name: Chockalingam

Phone No: 93620 24855

Email: piping@aes-group.in

Contact

Name: Poornima

Phone No: 98948 32125

Email: poornima.b@aes-group.in

It is pertinent that the clients’ building, campus, manufacturing facilities, and infrastructure in the plant are designed to effectively integrate electrical power, heating, cooling, and plumbing systems. AES can deliver with our detailing design options that prioritize your energy use requirements and goals in these critical systems.

Technical building Services for

Contact

Name: Poornima

Phone No: 98948 32125

Email: poornima.b@aes-group.in

AES is involved in the following activities as for as Electrical, Instrumentation and Automation (EIA) disciplines are concerned:

Our team is experienced in the detailed design of following equipment:

| Sl No | Equipment Name | Capacity | Make of Equipment |

|---|---|---|---|

| 01 | Switchyard panel | 132KV/400KV | ABB, Siemens, Areva, Alstom |

| 02 | TRANSFORMERS. Generator Transformer | 75 MVA | Alstom, Bharat Bijli, Voltamp, CGL, EMCO/ABB |

| 03 | Aux Transformer, Three winding Transformer and Zigzag Transformer | Up to 4 X 2.5 MVA | Voltamp, EMCO |

| 04 | Power Transformer | 45 MVA | Alstom, Bharat Bijli, Voltamp, CGL, EMCO |

| 05 | HT Panel | 5000Amps 40KA,3 sec | ABB, Siemens, Areva, Schneider and System control |

| 06 | Alternator | 1X60MW | TDPS, BHEL, APT, Va-tech, Jinan |

| 07 | Neutral Grounding Resistance Panel | 300Amps 63ohms | National Switchgears, RSI switchgear |

| 08 | LT Panel | 4500A panel | ABB, Siemens, L&T, industrial switchgear, and Cot make. |

| 09 | HT Bus duct, Segregated phase Bus duct | 3000Amps | C&S, Enpro, Spaceage, and spearhead |

| 10 | Isolated Phase Bus duct | C&S & Reep | |

| 11 | LT Bus duct, Non-Segregated phase Bus duct | Enpro, C&S, Busbar system | |

| 12 | HT & LT Cable XLPE | 630 Sqmm | Glostar, Universal, CCI, RPG, Finolex, Thermopad, KCI |

| 13 | DC system Panel & UPS panel. | 900AH | Amararaja ,HBL Nife ,Caldyne |

| 14 | UPS panel. | 60 kVA | Emerson, Hirel |

| 15 | AVR, Metering, synchronizing, Generator protection and Governor control panels | VEE VEE controls, & E&I Ltd | |

| 16 | Cable Tray | Up to 600 mm Tray | Our own make |

| 17 | Distribution Board | Our own make Component based on the customer requirement. | |

| 18 | Local Push Button | Our own make; Component based on the customer requirement. | |

| 19 | Fuel handling system accessories control panels | Respective vendor make | |

| 20 | Lighting and its accessories for all power building | Bajaj CGL, Wipro | |

| 21 | Earth Mat, Grid and respective equipment earthing | Based on the calculation | |

| 22 | VFD 12 & 6 pulse with line up panel (Both 690V &415V) | 750 kW | ABB, Siemens, Danfoss, Allan Broadly & L&T |

| 23 | HT Motors | 2500 kW | ABB, BHEL, Alstom |

Following panels can be manufactured by AES:

Our team has carried out a Renovation Life Assessment & Modernization (RLA) work at 2x210 MW Unit-1 of Sanjay Gandhi Thermal Power Station at BIRSINGHPUR, Madhya Pradesh in India.

The plant has PC fired Boilers, Turbine and Balance of the Plant (WTP, ACC, FHS, FFS, AC & P & V System, Burner Management system (BMS)) supplied by BHEL.

This total Renovation life assessment consultancy work was awarded by M/s. TÜV-SÜD South Asia Pvt. Ltd., INDIA New Delhi.

Experienced with the following DCS:

Experienced in following Communication Protocols:

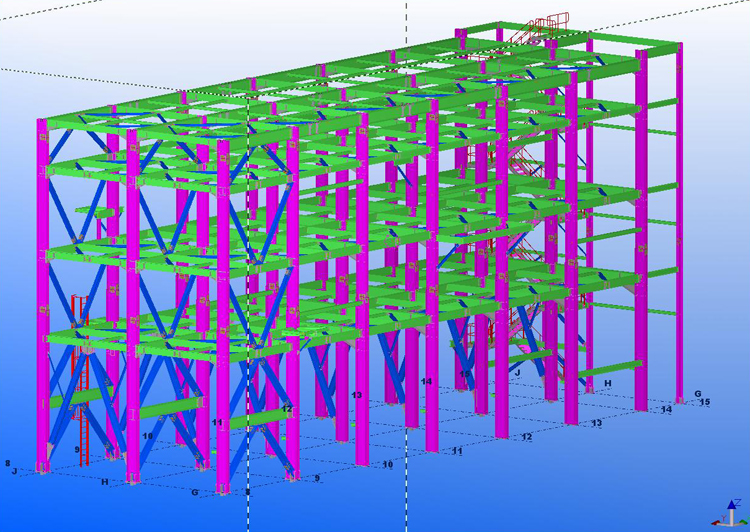

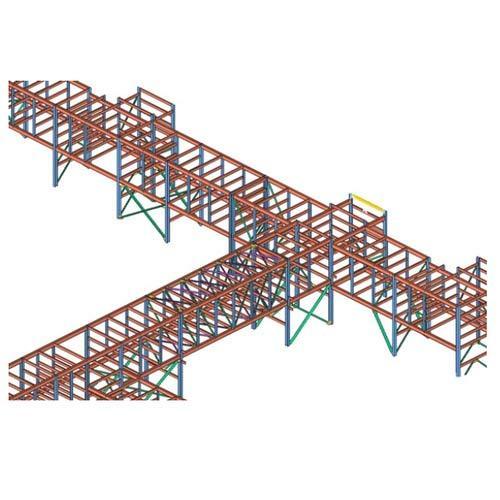

With the ever-increasing use of structural steelwork in high rise residential buildings, commercial complexes, oil and gas plants, industrial and commercial projects, AES has positioned itself to provide Structural steelwork, 3D modelling and shop detailing services and analyzing the steel structures of complex systems.

AES specializes in providing structural detailing and miscellaneous steel detailing to steel erectors, fabricators and general contractors. Our services are not limited to only steel detailing but extends to all aspects of steel fabrication.

Our capabilities include but not limited to the following:

Contact

Name: Poornima

Phone No: 98948 32125

Email: poornima.b@aes-group.in

In this competitive world of business, organizations strive hard to deliver the impossible at an accelerated pace to the market. They resort to broaden their design capabilities, enhance their engineering environment and trying to leverage their existing assets. Of course, all this needs to be done at a reduced cost!

Reverse Engineering is the solution for all this!

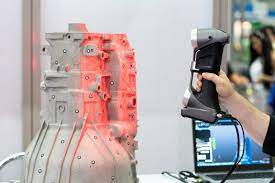

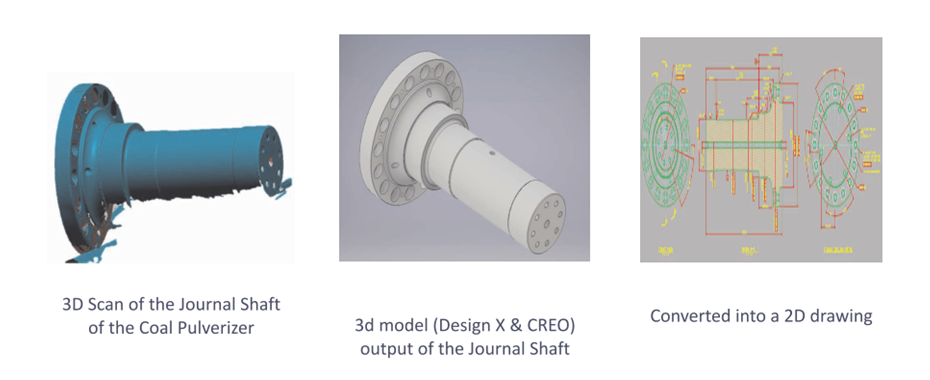

Reverse Engineering is the art of processing 3D scan data using the most comprehensive software to create feature based CAD, feature based editable solid models compatible with the existing CAD software.

Instead of starting from a blank screen, you can start from data created by the real world. You can create editable, feature- based CAD models from a 3D scanner and integrate them into your existing engineering design workflow.

Organizations at times are forced to create products that are close to impossible, or required to customize parts that require a perfect fit with the human body. Or to create components that integrate perfectly with existing products. Sometimes they need to recreate a complex geometry that cannot be measured any other way. These tasks are impossible without the use of Reverse Engineering.

Many designs are inspired by another. A complicated object or model of an inspiring design can be scanned and reverse engineered into your CAD system. You can learn from it. You can reuse it. You can improve upon it. You can easily rebuild your old parts into current CAD data, create drawings and production designs. You can scan prototypes, existing parts, tooling or related objects, and create designs in a fraction of the time compared to what it would take to manually measure and create CAD models from scratch. From product idea to finished design, a lot of weeks can be saved.

Contact

Name: Lakshmanan

Phone No: 95970 89134

Email: lakshmanan.s@aes-group.in